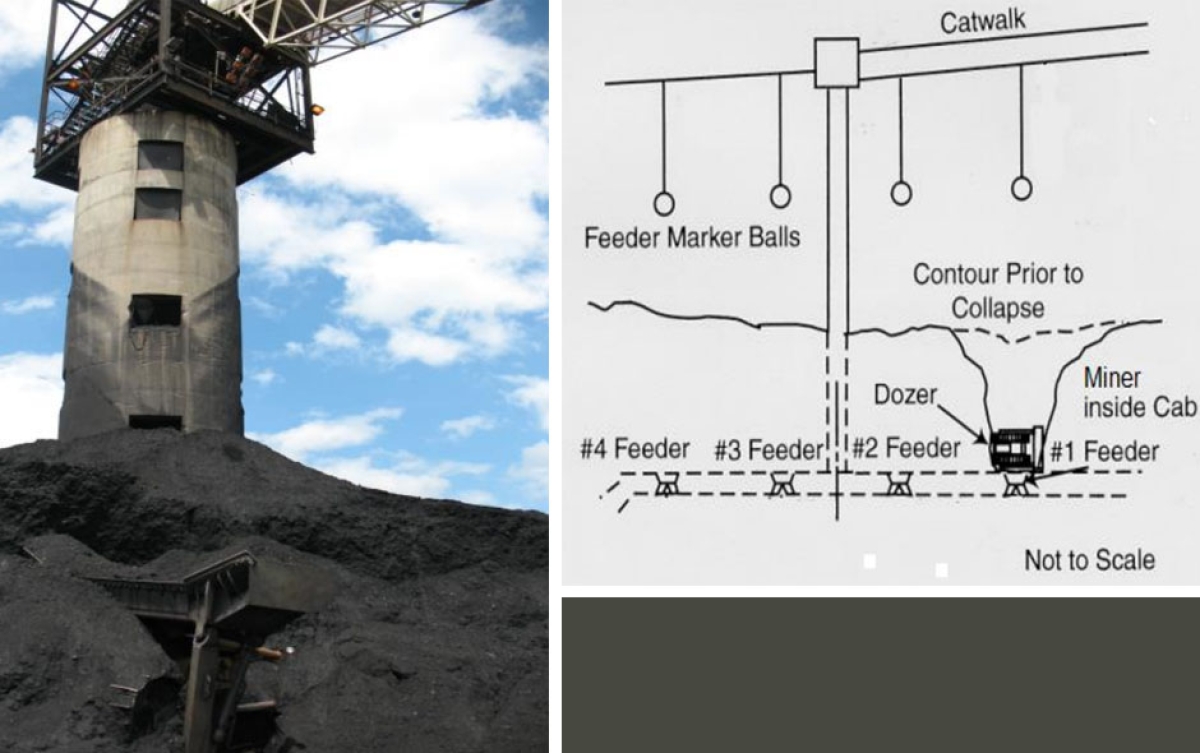

During calendar year 2015, seven dozers were involved in stockpile accidents. Most of the accidents involved the dozer falling into a hidden cavity created when material “bridged” over a feeder and material beneath the bridge was withdrawn. Bridging can occur when equipment compacts the material at the surface of the pile or if the surface material freezes. Stockpiles that have sat idle for a period of time can also become more prone to bridging due to consolidation of the pile material. None of the accidents involved injuries to miners; however, each had the potential to be serious.

Best Practices to Prevent Stockpile Accidents

- Implement a system to detect cavities and warn all potentially affected parties.

- Use safe procedures to eliminate a cavity.

- Never operate equipment directly over a feeder.

- Markers should be placed directly overhead of a feeder to indicate its location.

- Consider the installation of a proximity detection system to alert equipment operators if they are approaching a predetermined distance from the feeder.

- Install lights or signal systems that identify which feeders are operating.

- Always operate equipment facing the feeder.

- Special high strength safety glass should be installed in dozer cabs used on stockpiles.

- Equip stockpile dozers with a transmitter that sounds an alarm and stops feeders and belts when the signal is lost.

- Always securely store SCSR and flashlights in the dozer cabs.

- Provide specialized training to miners on alarm response, equipment needs and recovery of a disabled dozer. This can save time and potentially life.

For more information on stockpile safety, please visit MSHA’s Surge Pile Accident Prevention page.