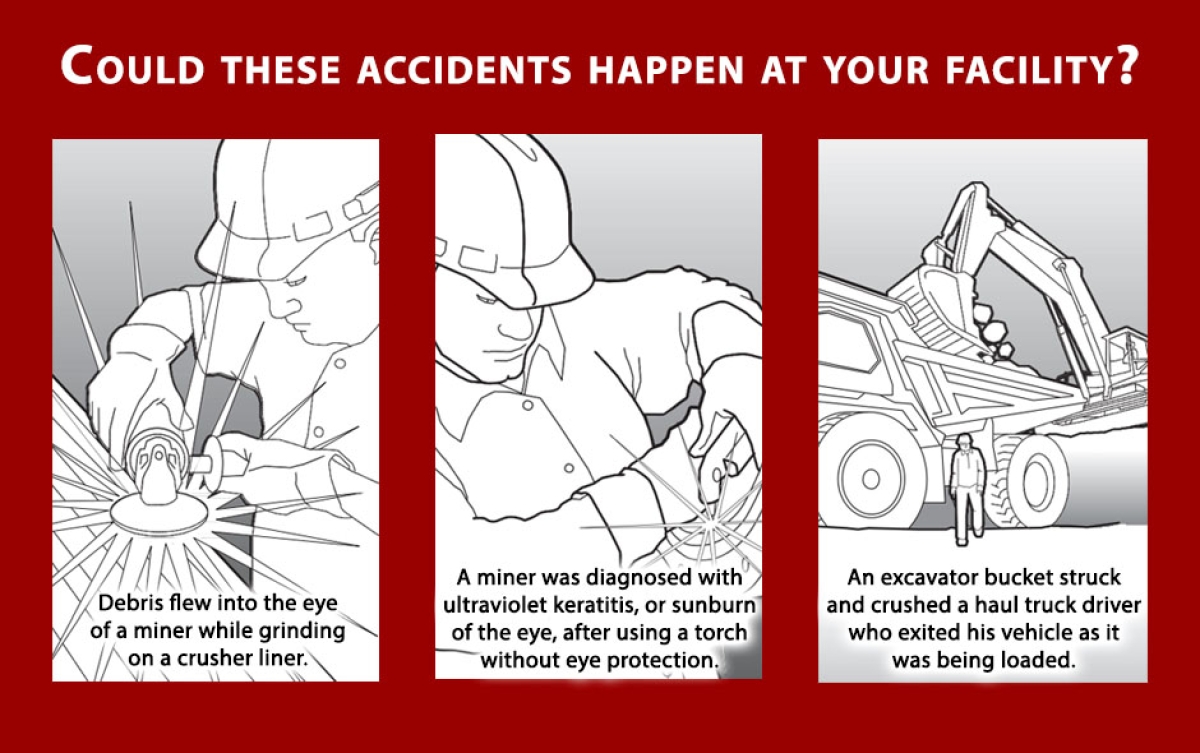

Equipment and Machinery Accidents are Commonly Reported

Access a collection of accidents involving machinery and equipment as well as associated best practices.

Use of Best Practices Can Eliminate These Kinds of Injuries

- Ensure that machinery is powered off and secured against hazardous motion before performing repairs or maintenance.

- Consider all energy hazards, including electrical, mechanical, pneumatic and hydraulic systems.

- When locking and tagging out equipment, use individual locks and tags and ensure miners have the keys to their locks. Personnel should not remove locks that are not their own.

- Inspect machinery prior to use. Tag and remove from service machinery that requires repairs.

More Information

Since 2011, 16 metal and nonmetal miners have died in accidents involving machinery and non-haulage mobile and quarry equipment, and many more have been seriously injured or disabled. Of the 16 persons fatally injured, six were supervisors and three were contractors. Seven miners died when they were struck by the equipment they or a co-worker were operating, four miners drowned when their equipment ran into or overturned into water, and five more died when they were caught in crushers, on drill steel or between reciprocating machinery. The equipment involved represented a wide variety of mining equipment: drills, dozers, excavators, graders, dredges and crushers.

MSHA standards require operators to maintain control of mobile equipment while it is in motion, and to operate at speeds consistent with conditions of mine roadways, tracks, grades, clearance, visibility and traffic. When mobile equipment is not in motion, it must be stopped in a safe location and when not attended, parked in a manner that prevents it from moving and becoming a hazard to the operator or other miners. In addition, mine supervisors and equipment operators need to continuously monitor and maintain roadways and berms and operate mobile equipment in a controlled, safe manner. When operating excavators, position them as far from the water’s edge as feasible on firm, stable ground. Don’t traverse unstable ground above a highwall and stay off and away from over-steepened stockpiles until they can be made safe.

Below are downloadable PDF links for this Machinery and Equipment Hazards Alert:

- English language poster

- Spanish language poster

- Collection of accidents involving machinery and equipment as well as associated best practices

You can use the photos and accident descriptions found in the Fatalgrams in this last link to prompt discussions about fatalities and how to prevent them.

This product was developed as part of the MSHA Alliance Program. It does not necessarily reflect the official views of MSHA. The MSHA Alliance Program is to promote miner safety and health through voluntary partnerships, which provide training and education, outreach, technical assistance, and a national dialog on mine safety and health. For more information, contact MSHA at (202) 693-9414.