In the matter of Petition for Modification

Mountain Coal Company, L.L.C. West Elk Mine

I.D. No. 05-03672 Docket No. M-2017-040-C

PROPOSED DECISION AND ORDER

On November 27, 2017, a petition was filed seeking a modification of the application of 30 C.F.R. § 75.364(b)(2) to the Petitioner's West Elk Mine, located in Gunnison County, Colorado. The Petitioner alleges that the proposed alternative method will provide a level of safety equal to that provided by 30 C.F.R. § 75.364(b)(2) and that traveling one of the affected entries is a diminution of safety.

The relevant portion of the petitioned standard is at 30 C.F.R. § 75.364(b)(2) and states:

(b) Hazardous conditions and violations of mandatory health or safety standards. At least every 7 days, an examination for hazardous conditions and violations of the mandatory health or safety standards referenced in paragraph (b)(8) of this section shall be made by a certified person designated by the operator at the following locations:

****

(2) In at least one entry of each return air course, in its entirety, so that the entire air course is traveled.

****

Petitioner proposes to establish multiple inlet and outlet evaluation points such that the air quality, air quantity, and air direction of all air entering and leaving the Sly Gulch South Mains Return is measured and evaluated at least every seven days in lieu of traveling one of the affected entries. Petitioner submits that the proposed alternative method will provide a level of safety equal to that provided by 30 C.F.R. § 75.364(b)(2) and that traveling one of the affected entries is a diminution of safety.

In the alternative to compliance with 30 C.F.R. § 75.364(b)(2), the Petitioner states the following:

You can now file your MSHA forms online at www.MSHA.gov. It's easy, it's fast, and it saves you money!

A. Multiple roof falls and floor heave within the proposed evaluation area limits the entries that can be traveled by the weekly examiner. Some of the traveled entries require the weekly examiner to crawl on his hands and knees, preventing quick egress if necessary.

B. All air entering and leaving the affected area can be measured and evaluated safely from the proposed inlet and outlet evaluation points shown on the attached drawing. Access to the proposed inlet and outlet evaluation points is not hindered by roof falls or excessive floor heave, allowing quick egress if necessary.

C. There are no seals or electrical installations within the proposed evaluation area that must be examined.

D. In lieu of traveling one of the return entries in the proposed evaluation area, at least every seven days, a certified person will:

I. Measure the air quantity at each inlet and outlet evaluation point. If the combined air quantity at the outlet evaluation points differs by more than 20% from the combined air quantity at the inlet evaluation points, ventilation controls surrounding the affected area will be examined from the outby side and corrective measures will be implemented to repair the affected ventilation controls to restore the differential air quantities to within 20%.

II. Measure the air quality at each inlet and outlet evaluation point. Both the methane and oxygen concentrations will be measured. Methane concentrations at the inlet and outlet evaluation points will be limited to 2.0%. Oxygen concentrations at the inlet and outlet evaluation points will be a minimum of 19.5%.

III. Verify the proper air direction as indicated on the drawing at each inlet and outlet evaluation point.

IV. Record the air quantity, air quality, and a notation of proper air direction at each inlet and outlet evaluation point in the Weekly Examination Book.

MSHA personnel conducted an investigation of the petition and filed a report of their findings with the Administrator for Coal Mine Safety and Health. After a careful review of the entire record, including the petition and MSHA's investigative report, this Proposed Decision and Order is issued.

Findings of Fact and Conclusions of Law

The mine employs 292 people, including 215 underground miners. Approximately 70 miners are underground each shift, including management personnel. The mine produces coal on two rotating shifts per day, five days per week, totaling 18 hours of production daily. There is one maintenance shift per day, five days a week.

The mine operates in the "E'' Seam with three active MMU's- two continuous miner section and one longwall section and produces approximately 15,865 tons daily.

Production for mine is approximately 4.4 million tons per year. The mine liberates an average of 2,927,787 cubic feet of methane every 24 hours and is currently on a 103(i) 5 day spot inspection. The methane liberation from the "F" and "B" coal seams that exhaust through the Sly Gulch fan, average 1,176,529 cubic feet of methane every 24 hours. Diesel-powered ram cars and belt conveyors transport the coal to the surface. Diesel-powered equipment move men and materials.

The MSHA investigation found that the area the weekly examiner travels is only accessible along a path approximately 2 feet wide along the rib lines measuring approximately 46 - 65 inches in height. Due to the floor heaving conditions down the center of the entry, the clearance height down the center is only 24- 30 inches. The adjacent entries have become impassible due to deteriorating roof and floor heaving conditions. The roof along this route is also deteriorating between the roof bolts and pans. There is no roof mesh installed in this area. This area of the mine was developed from 1982 through 1986. Multiple roof falls and floor heave within the proposed evaluation area limits the entries that can be traveled by the weekly examiner. Some of the traveled entries require the weekly examiner to crawl on his hands and knees, preventing quick egress if necessary. There are no seals or electrical installations within the proposed evaluation area that must be examined.

Miners at the West Elk Mine are not represented by a labor organization, and there are no representatives of miners at the mine. A copy of the proposed petition for modification is posted on the mine1s bulletin board. There was no opposition to this petition. All of the managers and miners who were interviewed stated it should be granted.

On the basis of the petition and the findings of MSHA1s investigation, Mountain Coal Company, L.L.C. request for a modification of the application of 30 C.F.R. § 75.364(b)(2) to its West Elk Mine is hereby granted and the following order issued.

ORDER

Wherefore, pursuant to the authority delegated by the Secretary of Labor to the Administrator for Coal Mine Safety and Health, and pursuant to Section 101(c) of the

Federal Mine Safety and Health Act of 1977, 30 U.S.C. § 811(c), it is ordered that Mountain Coal Company, L.L.C. Petition for Modification of the application of 30

C.F.R. § 75.364(b)(2) in the West Elk Mine is hereby:

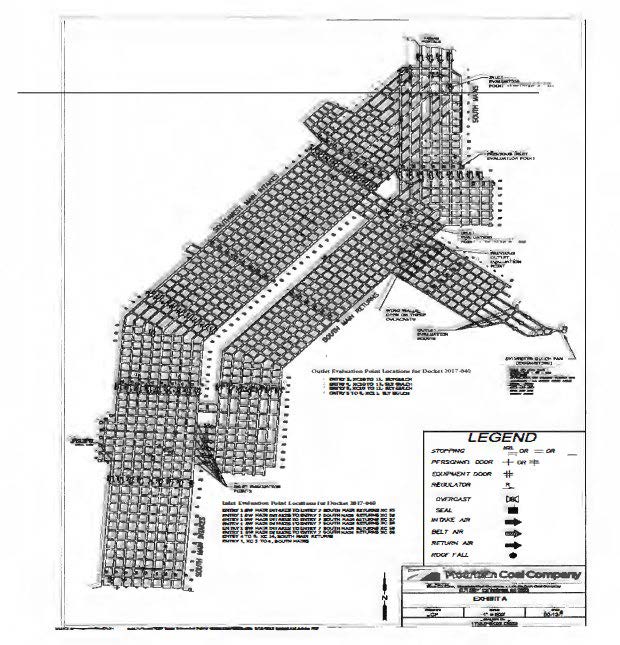

GRANTED, for establishing evaluation points at eight inlet locations and four outlet locations (please see Exhibit A map enclosed). The air quality, air quantity, and air direction of all air entering and leaving the Sly Gulch South Mains Return shall be measured and evaluated at least every seven (7) days in lieu of traveling one of the affected entries conditioned upon compliance with the following terms and conditions:

1. The eight inlet evaluation points for monitoring airflow will allow for effective evaluation of airflow from the South Main Intakes to ventilate the South Mains Return, please see Exhibit A map. The evaluation points shall be established as follows:

1. Entry 1 SW Main Intakes to Entry 7 South Main Returns XC 55

2. Entry 1 SW Main Intakes to Entry 7 South Main Returns XC 56

3. Entry 1 SW Main Intakes to Entry 7 South Main Returns XC 57

4. Entry 1 SW Main Intakes to Entry 7 South Main Returns XC 58

5. Entry 1 SW Main Intakes to Entry 7 South Main Returns XC 59

6. Entry 1 SW Main Intakes to Entry 7 South Main Returns XC 60

7. Entry 4 to 5, XC 14, South Main Returns

8. Entry 1, XC 3 to 4, South Mains

2. The four outlet evaluation points for monitoring airflow will allow for effective evaluation of airflow from the South Main Intakes used to ventilate the South Mains Return, please see Exhibit A map. The evaluation points shall be established as follows:

1. Entry 3, XC 10 to 11, SLY GULCH

2. Entry 4, XC 10 to 11, SLY GULCH

3. Entry 5, XC 10 to 11, SLY GULCH

4. Entry 5 to 6, XC 11, SLY GULCH

3. Signs showing the safe travel route to each monitoring station shall be conspicuously posted in an adjacent travel entry.

4. A certified person shall conduct examinations every 7 days at each of the monitoring stations. The examinations shall include the quantity and quality of air entering or exiting the monitoring station. The examinations shall also include a determination of any airflow from adjacent entries, defined and measured as stated in Paragraph 9 below. All air quality measurements shall be made using MSHA approved and calibrated hand-held multi-gas detectors to check the

methane and oxygen gas concentrations and appropriate, calibrated anemometers to check airflow volume.

5. A diagram and/ or enlarged map showing the normal direction of the airflow and location of inlet and outlet evaluation point locations shall be posted at the monitoring stations. The diagram shall be maintained in legible condition and any change in airflow direction shall be reported to the mine foreman for immediate investigation and corrective action.

6. The certified person shall certify by date, time and initials, on a date board provided at each monitoring station, that the examination was made. The certified person shall record the results of the examination, including the condition of the accessible permanent ventilation controls creating the aircourse, in ·a book kept on the surface and made accessible to all interested parties. The certification, record keeping, and retention period requirements of 30 C.F.R. § 75.364(g), (h), and (i) shall be met.

7. All monitoring station(s) and approaches to monitoring station(s) shall, at all times, be maintained in a safe condition. The roof shall be adequately supported to prevent deterioration in the vicinity of the stations. The monitoring stations and routes of travel to the monitoring stations shall be kept free of water accumulations and any other obstructions.

8. Methane gas or other harmful, noxious or poisonous gases shall not be permitted to accumulate in excess of legal limits for return air as stipulated in the 30 C.F.R.

§§ 75.321, 75.322 and 75.323. An increase of 0.3 percent methane above the last previous methane reading or a 10 percent change in air flow quantity shall cause an immediate investigation of the affected area. The results of the investigation shall be immediately reported to the mine foreman who shall take appropriate corrective action.

9. The initial airflow from adjacent aircourses shall be determined during the first evaluation following implementation of this modification. Airflow from adjacent aircourses is defined as the difference between the air quantity entering and exiting the petitioned area, as measured at the monitoring stations. A 10 percent change from the initial airflows in the aircourse shall cause immediate investigation and evaluation of the cause. Appropriate corrective action must then be taken. Following corrective action a new "initial airflow" shall be determined and serve as the basis for subsequent evaluations.

10. The monitoring station location(s) shall be shown on the annually submitted mine ventilation map in accordance with 30 C.F.R 75.372.

The stations shall not be moved to another location without prior approval by the District Manager as part of the Ventilation Plan for the mine.

11. Prior to implementing this modification, all mine personnel shall be instructed that, except along designated routes, no travel into the petitioned area shall be permitted and all other approaches shall be fenced off or barricaded with "DO NOT ENTER'' warning signs. Entry in the area shall be permitted only to conduct investigations and correct problems with air flow detected through the monitoring process. All such work shall be done under the supervision of a certified person. All persons who work in the area shall be instructed in the emergency evacuation procedures and all provisions of 30 CFR 75.1502, 75.1504 and 75.1505.

12. Within 60 days after this Proposed Decision and Order becomes final, the Petitioner shall submit proposed revisions for its approved 30 CFR Part 48 training plan to the Coal Mine Safety and Health District Manager. These proposed revisions shall specify initial and refresher training regarding the alternative method outlined in the petition and the terms and conditions stated in the Proposed Decision and Order. The procedures of 30 C.F.R. 48.3 for approval of proposed revisions to the already approved training plans shall apply.

Any party to this action desiring a hearing on this matter must file in accordance with 30 C.F.R. § 44.14, within 30 days. The request for hearing must be filed with the Administrator for Coal Mine Safety and Health, 201 12 th Street South, Arlington, Virginia 22202-5452. If a hearing is requested, the request shall contain a concise summary of position on the issues of fact or law desired to be raised by the party requesting the hearing, including specific objections to the proposed decision. A party other than Petitioner who has requested a hearing shall also comment upon all issues of fact or law presented in the petition, and any party to this action requesting a hearing may indicate a desired hearing site. If no request for a hearing is filed within 30 days after service thereof, the Decision and Order will become final and must be posted by the operator on the mine bulletin board at the mine.

____/s/____

Timothy R. Watkins

Deputy Administrator for

Coal Mine Safety and Health

Certificate of Service

I hereby certify that a copy of this proposed decision was served personally or mailed, postage prepaid, or provided by other electronic means this 15th day of October , 2018, to:

Mr. A. Bill Olsen Safety Director

Mountain Coal Company, L.L.C. 5174 Highway 133

Somerset, CO 81434

bolsen@a rchcoal.com

____/s/_______

Tammi Carrington

Secretary

cc: Mr. Bill York- Feirn, Chief Inspector, Colorado Division of Mines, Department of Natural Resources 1313 Sherman Street, Denver, CO 80203

Bill.York-Feirn@state.co.us