11/14/2022

In the matter of Petition for Modification

Mingo Logan Coal LLC

Mountaineer II Mine

I.D. No. 46-09029 Docket No. M-2021-044-C

PROPOSED DECISION AND ORDER

On December 20, 2021, Mine Safety and Health Administration confirmed receipt of a petition seeking a modification of the application of 30 CFR §75.503 to Petitioner’s Mountaineer II Mine located in Logan County, West Virginia. The petitioner requested the modification to allow the use of trailing cables exceeding the length specified in 30 CFR §18.35(a)(5)(i). The petitioner alleges that the alternative method proposed in the petition will at all times guarantee no less than the same measure of protection afforded by the standard.

30 CFR §75.503 provides in part:

The operator of each coal mine shall maintain in permissible condition all electric face equipment required by §§75.500, 75.501, and 75.504 to be permissible which is taken into or used inby the last open crosscut of any such mine.

30 CFR §18.35(a)(5)(i) provides in part:

(5) Ordinarily the length of a portable (trailing) cable shall not exceed 500 feet. Where the method of mining requires the length of a portable (trailing) cable to be more than 500 feet, such length of cable shall be permitted only under the following prescribed conditions:

(i) The lengths of portable (trailing) cables shall not exceed those specified in Table 9, Appendix 1, titled “Specifications for Portable Cables Longer than 500 Feet.”

On February 25, 2022, MSHA personnel initiated an investigation into the merits of the petition. An investigation report was written and the findings of the report was filed with the Administrator for Mine Safety and Health Enforcement. After a careful review of the entire record, including the petition and MSHA’s investigative report, and responses from requests for additional information the Administrator issues this Proposed Decision and Order.

Findings of Fact and Conclusions of Law

Mingo Logan Coal LLC is seeking a modification of the application of Title 30 Code of Federal Regulations (CFR) 75.503 (Schedule 2G, 18.35), at its Mountaineer II Mine, ID No.

46-09029, located in Logan County, West Virginia, proposing alternative methods of compliance to permit the operator to extend cable lengths up to 1000 maximum feet. In support of its petition, Mingo Logan states the following:

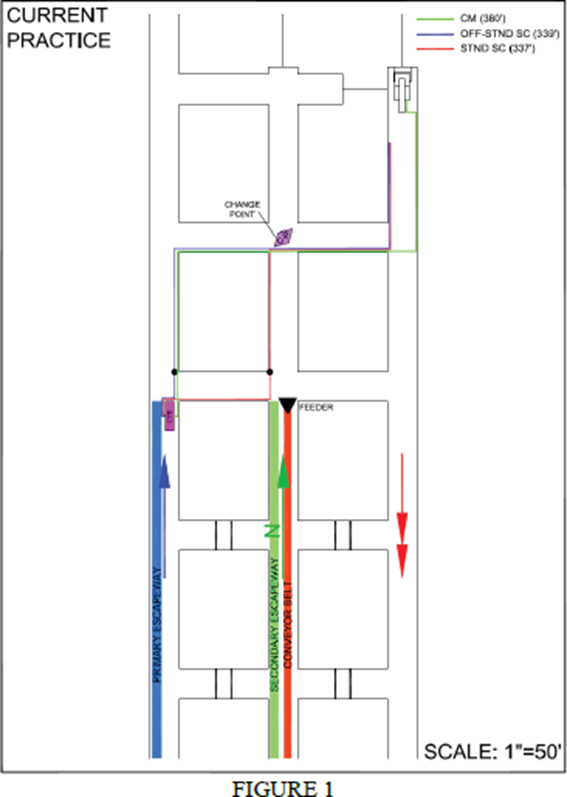

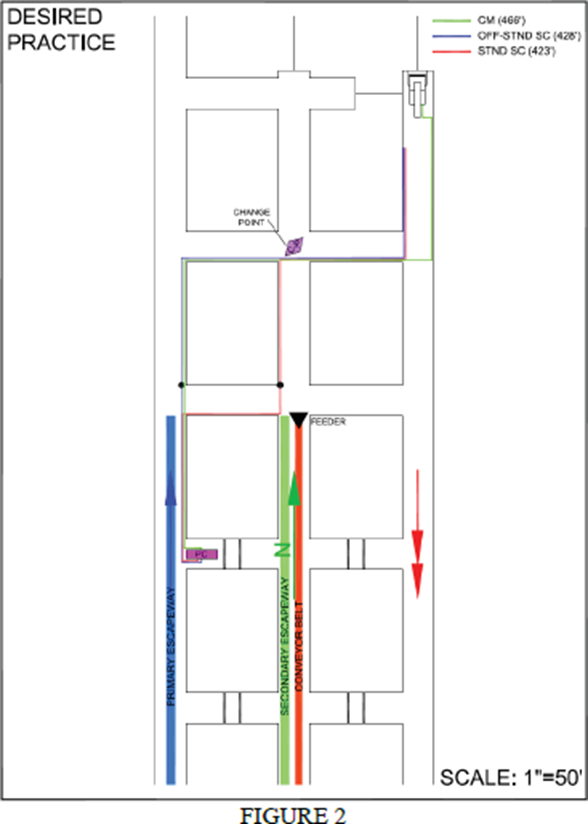

The Mine plan requires large pillars to be left for roof control requirements. The larger pillars will require longer distances for machines to travel to the working face. The Petitioner depicts in the current practice (FIGURE 1), with the power center located two crosscuts outby the face in the number one entry of a three-entry mining section where the maximum cable length is 380 feet, which is in accordance with Schedule 2G, 18.35(5). The desired practice (FIGURE 2) depicts larger pillars needed for roof control with the power center in the No.1 to No.2 entry crosscut. The proposed desired alternate method will provide the following benefits:

Extending the maximum lengths to 1000 feet prevents the risk of cable damage and potential operator injury in the event a machine travels beyond the 500 feet length, breaking the cable. It would be easy for an operator to lose track of how much cable is on the reel and overextend the distance. Note that the cable length during normal production will be 466 feet which is extremely close to the 500 feet limitation. It is evident that extending the maximum cable lengths to 1000 feet when mining larger pillars mitigates a potential safety hazard of a cable breaking and striking an operator.

The entry that the power center is currently located in is the air intake entry, which is also the primary escapeway. 1000-foot cables will allow the Power Center to be located in a crosscut instead of leaving the Power Center in the escapeway, providing unobstructed egress from the mine during an evacuation event. Though the larger pillars do not require the Power Center to be placed in a crosscut it is evident that there is a safety improvement when the Power Center is located in a crosscut rather than the primary escapeway.

The entry that the power center is located in is currently the intake air entry, which is partially obstructing the intake ventilation. This complicates the ventilation system because the area for which the power center and cables occupy increases overall restriction at the section’s intake dumping point. This further complicates ventilation because belt air intake is utilized throughout the mine and a strict balance between intake and belt air intake must be maintained per regulation and the approved ventilation plan. This balance pertains to both pressure differential from intake to neutral as well as keeping belt air intake at or below 50% of the total air quantity being delivered to the section.

Conditioned upon compliance with the following terms and conditions:

1. The maximum length of the 995-volt, three phase, alternating current trailing cables shall not exceed 1,000 feet in length and the trailing cable shall have a 90-degree Celsius insulation rating. The maximum length of the 600-volt, three phase, alternating current,

trailing cables supplying section Loading machines, roof bolters, and shuttle cars shall not exceed 1,000 feet in length and the trailing cable shall have a 90-degree Celsius insulation rating.

2. The trailing cable shall not be smaller than No. 2/0 AWG for the continuous mining machine.

3. The trailing cables shall not be smaller than No.2 AWG for the section roof bolting machines, and shuttle-cars.

4. All Circuit Breakers used to protect No. 2/0 AWG cables not to exceed 1000 feet in length shall have instantaneous trip units set to trip at 1,500 amperes. The trip settings of these Circuit Breakers shall be sealed and these Circuit Breakers shall have permanent, legible labels. The label shall identify the Circuit as being suitable for protecting 2/0 AWG cables.

5. Replacement Circuit Breakers and/or instantaneous trip units, used to protect No. 2/0 AWG trailing cables, shall be set to trip at 1,500 amperes and this setting shall be sealed.

6. All Circuit Breakers used to protect No. 2 AWG trailing cables not to exceed 1000 feet in length shall have instantaneous trip units set to trip at 600 amperes. The trip setting of these Circuit Breakers shall be sealed, and these Circuit Breakers shall have permanent, legible labels. The labels shall identify the Circuit Breakers as being set for the size of the cable.

7. Replacement Circuit Breakers and/or instantaneous trip units, used to protect No. 2 AWG cables shall be set to trip at 600 amperes and this unit shall be sealed.

8. During each production day, persons designated by the operator shall visually examine the trailing cables to ensure that the cables are in safe operating condition and that the instantaneous settings are sealed and do not exceed the settings stipulated in items No. 4, and 6.

9. Any trailing cable that is not in safe operating condition shall be removed from service immediately and repaired or replaced.

10. Each splice or repair in the trailing cable shall be made in a proper workmanlike manner and in accordance with the instructions of the manufacturer of the splice or repair kit. The outer jacket of each splice or repair shall be vulcanized with flame resistant material or made with material that has been accepted by MSHA as flame resistant.

11. In the event that mining methods or operation procedures cause or contribute to the damage of any trailing cable, the cable shall be removed from service immediately, repaired or replaced, and additional precautions shall be taken to ensure that, in the future, the cable is protected and maintained in a safe operating condition.

12. Permanent warning labels shall be installed and maintained on the covers of each Circuit Breaker and the trailing cable disconnecting device(s) indicating that the trailing cable can only be connected to a properly adjusted and sealed Circuit Breaker. These labels shall warn Miners not to change or alter the sealed short Circuit settings and warn them not to connect the trailing cables to an improperly adjusted Circuit Breaker.

13. The petitioner’s alternative method shall not be implemented until all Miners who have been designated to examine the integrity of the seals, verify the short-Circuit settings, and examine trailing cables for defects have received the elements of training specified in item 14.

14. Within 60 days after this proposed decision and order becomes final, the petitioner shall submit proposed revisions to its approved 30 CFR Part 48 training plan to the coal mine safety and health district manager in which the mine is located. These proposed revisions shall specify task training for Miners designated to verify that the short-Circuit settings of the Circuit interrupting device(s) that protect the affected trailing cables do not exceed the specified settings. The training shall include the following elements:

a. The hazards of setting the short-Circuit interrupting device(s) too high to adequately protect the trailing cable.

b. How to verify that the Circuit interrupting device(s) protecting the trailing cable(s) are properly set and maintained.

c. Mining methods and operating procedures that will protect the trailing cable(s) against damage; and

d. Proper procedures for examining the affected trailing cables to ensure that the cables are in safe operating condition.

Mingo Logan Coal LLC provides a fault study diagram indicating the available fault current for the circuits.

MSHA’s investigation finds that Mingo Logan Coal LLC, Mountaineer Mine extracts bituminous coal from the No. 2 Gas and Alma coal seams. This mine currently employs 305 persons, including supervisory personnel. The average mining height is 72 inches. The mine is ventilated with 1 exhaust fan and currently liberates 4,354,424 Cubic feet of methane in a 24- hour period. This mine has five mechanized mining units (MMU's) and one construction unit, all of which employ continuous mining machines. The mine operates two production shifts and one maintenance shift, five days each week with an average of 10,000 raw tons mined each day.

Those participating are listed in the chart below.

Dave Porter Mingo Logan Coal Co Superintendent

Todd Collins Mingo Logan Coal Co Mine Foreman

Ronnie Mullins Mingo Logan Coal Co Maintenance Manager

Bruce Epperheart Mingo Logan Coal Co Assistant Maintenance Manager

Keith Duncan Mingo Logan Coal Co Maintenance Foreman

Greggory Ward Mine Safety and Health Adm. Electrical Supervisor

Mountaineer II Mine is not a union operation, and a representative of the miners was not selected. However, the petition was discussed with a representative number of miners employed at this mine and no one provided any comments. The petition is posted on the bulletin board.

The granting of this Petition for Modification would affect all miners working on the MMU's

The investigation determined the mine no longer operates a longwall, therefore does not utilize the three-entry gate system method of mining illustrated in the application. The area pertaining to the petition will be developed in the Spruce Mines and the 2 Gas Sub-mains portion of the mine. The operator is protected to develop multiple common intake entries, thereby eliminating the need for the section power center to be positioned in a crosscut. Also, based on the current mine projections on file in the MSHA Pineville District Office, it was determined that the basic adjustments could be made to the section arrangement and work practices which would allow for normal operation using trailing cables sized per the specification of 30 CFR Section 18 Subpart D, Appendix I Table 9.

During the meeting MSHA asked those in attendance for clarification regarding the petitioner’s claim that extended cable lengths would mitigate a potential safety hazard of a cable breaking and striking an operator. The company officials did not provide a response or provide any additional comments pertaining to the question.

The petitioner did not provide the necessary contents required. According to 30 CFR §44.11 (a) a petition for modification filed pursuant to 30 CFR §44.10 shall contain the follow contents included in (1-6).

30 CFR §44.11 (a)(5) provides in part:

(5) A detailed statement of the facts the petitioner would show to establish the grounds upon which it is claimed a modification is warranted.

The petitioner request longer trailing cables for continuous mining machines, loading machines, roof bolting machines, and shuttle cars. MSHA has reviewed many petitions for this mandatory standard. Petitioners make requests or desires however desires and request do not meet the minimum requirements of the standard having established the grounds upon which it is claimed a modification is warranted. The facts that were provide by the petitioner were not supported or substantiated through the investigation. The petitioner claimed the use of a three-entry gate system however the three-entry gate system is no longer used or projected to be used at this mine in the near future. In this case, the petitioner requests to extend trailing cable length for unspecified number and type of mining equipment including continuous mining machines, loading machines, roof bolting machines, shuttle cars are not supported by facts. This request falls short of providing facts warranting the proposed extension of trailing cable lengths. The petitioner includes the mine operator’s mining methods including proposed gate entries however these gate entries are not consistent with the current mining practices and does not support the modification request.

The petitioner does not provide specific facts for MSHA approved mining equipment including the electrical load characteristics. According to the regulation this information is considered necessary contents of the petition that is required to be filed with the Director, Office of Standards, Regulations, and Variances.

After careful review of the entire record, including the petition, MSHA's investigative report, and responses from requests for additional information MSHA finds that the petitioner does not provide the contents that petition shall contain and the alternate method proposed by the petitioner does not provide an alternative method of compliance that will at all times guarantee no less than the same level of protection afforded to the miners.

ORDER

Wherefore, pursuant to the authority delegated by the Secretary of Labor to the Administrator for Mine Safety and Health Enforcement, and pursuant to Section 101(c) of the Federal Mine Safety and Health Act of 1977, 30 U.S.C., Sec. 811(c), it is ordered that Mingo Logan Coal LLC’s Petition for Modification of the application of 30 CFR § 75.503 at Mountaineer II Mine is hereby:

DENIED

Any party to this action desiring a hearing on this matter must file in accordance with 30 CFR

§44.14, within 30 days. The request for hearing must be filed with the Administrator for Mine Safety and Health Enforcement, 201 12th Street South, Arlington, Virginia 22202-5452.

If a hearing is requested, the request shall contain a concise summary of position on the issues of fact or law desired to be raised by the party requesting the hearing, including specific objections to the proposed decision. A party other than Petitioner who has requested a hearing may also comment upon all issues of fact or law presented in the petition, and any party to this action requesting a hearing may indicate a desired hearing site. If no request for a hearing is filed within 30 days after service thereof, the Decision and Order will become final and must be posted by the operator on the mine bulletin board at the mine.

Timothy R. Watkins

Deputy Administrator

for Mine Safety and Health Enforcement

Certificate of Service

I hereby certify that a copy of this proposed decision was served personally or mailed, postage prepaid, or provided by other electronic means this 14th day of November, 2022, to:

Johnathan Hensley,

Mine Manager Mountaineer II Mine

Rt. 17, P.O. Box E

Sharples, WV 25183

jhensley@archrsc.com

Garrett Barton,

General Manager Mountaineer II Mine

State Route 17,

Mountain Laurel Dr.

Sharples, WV 25183

gbarton@archrsc.com

Rodney Adamson

Mine Safety and Health Enforcement Specialist

cc: Eugene White, Director, Office of Miners' Health Safety & Training, 1615 Washington Street E, Charleston, WV 25311, Eugene.E.White@wv.gov