02/27/2025

In the matter of PETITION FOR MODIFICATION

Greenbrier Minerals, LLC

Eagle No. 1 Mine, Mine I.D. No. 46-09563

Lower War Eagle, Mine I.D. No. 46-09319

Muddy Bridge, Mine I.D. No. 46-09514

Powellton #1 Mine, Mine I.D. No. 46-09217 Docket No. M-2024-049-C

PROPOSED DECISION AND ORDER

On September 12, 2024, Greenb1ier Minerals, LLC filed a petition seeking modification of the application of 30 C.F.R. § 75.1002(a) at its Eagle No. 1 Mine in Logan County, WV, Lower War Eagle in Wyoming County, WV, Muddy Bridge in Logan County, WV, and Powellton #1 Mine in Logan County, WV. The petitioner alleges that the alte1native method in the petition will at all times guarantee no less than the same measure of protection afforded to the miners by the standard.

The petitioned standard, 30 C.F.R. § 75.1002(a) - Permissible electric equipment states,

Electric equipment must be permissible and maintained in a permissible condition when such equipment is located within 150 feet of pillar workings or longwall faces.

The petitioner is requesting a modification of the standard to allow the use of unapproved Powered Air Purifying Respirators (PAPRs) within 150 feet of pillar workings or longwall faces. Specifically, the petitioner is requesting to utilize the 3M Versaflo TR-800 Intrinsically Safe (Versaflo TR-800) PAPR motor/blower and batte1y with batte1y pack. The CleanSpace EX PAPR was granted in a previous Proposed Decision and Order, Docket Number M-2022-040-C on July 31, 2023.

The petitioner states that:

1. It currently uses the MSHA-approved 3M Airstream Headgear-Mounted (Airstream) PAPR System to protect miners working on its continuous miner sections. The Airstream provides a constant flow of filtered air to protect against potential exposure to respirable coal mine dust during normal mining conditions inby the last open crosscut. The Airstream is being discontinued by the manufacturer, no replacement components will be available, and there are no other MSHA-approved units.

2. The Versaflo TR-800 PAPR with motor/blower and battery qualifies as intrinsically safe, based on reports by the International Electrotechnical Commission Systems for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres (IECEx). The blower is certified by Underwriter Laboratories (UL) with an intrinsically safe rating of Division 1: Class I, II, III; Division 1: Groups C, D, E, F, G; T4 under the current standard of UL 60079; ATEX-certified with a rating of “ia.” The Versaflo TR-800 is rated and marked “Ex ia I MA, Ex ia IIB T4 Ga, Ex ia IIIC 135oC Da; -20oC ≤ TA ≤ +55oC.”

3. The Versaflo TR-800 PAPRs provide a constant flow of air inside the headtop or helmet. This airflow provides respiratory protection and comfort in hot working conditions.

4. The Versaflo TR-800 is not MSHA-approved as permissible, and 3M is not currently pursuing MSHA approval.

5. The alternative method in the petition will at all times guarantee no less than the same measure of protection afforded to the miners by the mandatory standard.

The petitioner’s alternative method addresses training, inspections, examinations and records, servicing, continuous monitoring for methane and procedures when 1.0 percent or more methane is detected, battery chargers, battery charging and change out procedures, and special precautions for lithium batteries. These proposed terms and conditions for the use of Versaflo are consistent with those approved by MSHA for previous petitions, with one exception.

The petitioner did not include the following condition regarding treatment of lithium batteries approaching the end of their life cycle: “The battery must not be used at the end of its life cycle (i.e., when there is a performance decrease of greater than 20% in battery-operated equipment). The battery must be disposed of properly.” The electrolyte used in Lithium-ion batteries is volatile and can ignite under certain circumstances, including overcharging. MSHA requires inclusion of this additional condition to reduce the possibility of thermal runaway, and a subsequent fire or explosion caused by a battery self-igniting.

MSHA personnel investigated the merits of the petition and filed a report of their findings with the Administrator for Mine Safety and Health Enforcement. After a careful review of the entire record, including the petition and MSHA's investigative report, the Administrator issues this Proposed Decision and Order.

Findings of Fact and Conclusions of Law

MSHA investigated pertinent details of the petition on January 21, 2025 at the Lower War Eagle Mine through a Teams meeting with individuals from the petitioned mines of the Eagle No. 1 Mine, Lower War Eagle, Muddy Bridge, and Powellton #1 Mine. This investigation included an item-by-item review of the proposed petitions, equipment manufacturer’s user instructions, Versaflo TR-800 brochures, and an onsite mine visit.

During the onsite visits, the MSHA investigator verified that the proposed Petitions for Modifications (PFM) were posted on the mine’s bulletin board and explained the PFM process and all stipulations to the miners and supervisors. Onsite mine visits were conducted at the Muddy Bridge and Eagle #1 Mine on January 23, 2025.

The following individuals participated in the January 21, 2025 investigation on behalf of Greenbrier Minerals, LLC:

1. Tom Canterbury, Safety Director

2. Jamey New, Manager

3. Scotty Brown, Superintendent

4. Allen Lardeiri, Safety Representative

5. Chris Mullins, Corporate

6. Chris Blackburn, Safety Representative

7. Clinton Craddock, Safety Representative

8. Kyle Cook, Safety Representative

9. Greg Gravely, Dust Technician

There are no Miner Representatives at Greenbrier Minerals, LLC and they are not union affiliated.

Below are descriptions of each mine during this investigation:

Greenbrier Minerals, LLC Lower War Eagle (46-09319) mines bituminous coal from the Lower War Eagle Seam. This mine currently employs 167 persons, including supervisory personnel. The average mining height is maintained at 68 inches. The mine is ventilated with an exhausting fan. The mine currently liberates 876,065 Cubic feet of methane in a 24-hour period. This mine has three mechanized mining units that are all continuous mining units. This mine is in producing status with two production shifts and a maintenance shift daily.

Greenbrier Minerals, LLC Muddy Bridge (46-09514) mines bituminous coal from the No.2 Gas Seam. This mine currently employs 119 persons, including supervisory personnel. The average mining height is maintained at 60 inches. The mine is ventilated with a blowing fan. The mine currently liberates a non-determined Cubic feet of methane in a 24-hour period. This mine has four mechanized mining units and all four are continuous mining units. This mine is in producing status with two production shifts and one maintenance shift daily.

Greenbrier Minerals, LLC Powellton #1 Mine (46-09217) mines bituminous coal from the Powellton Seam. This mine currently employs 67 persons, including supervisory personnel. The average mining height is maintained at 60 inches. The mine is ventilated with a blowing fan. The mine currently liberates O Cubic feet of methane in a 24-hour period. This mine has two mechanized mining units at this time. This mine has 2 production shifts with one maintenance shift daily.

Greenbrier Minerals, LLC Eagle 1 Mine (46-09563) mines bituminous coal from the No.2 Gas Seam. This mine currently employs 181 persons, including supervisory personnel. The average mining height is maintained at 68 inches. The mine is ventilated with a blowing fan. The mine currently liberates non-determined Cubic feet of methane in a 24-hour period. This mine has 6 mechanized mining units that are all continuous mining units. This mine is in producing status with two production shifts and one maintenance shift daily.

Between January 21st and 23rd 2025, tests were performed by MSHA Inspectors to determine if there was any electromagnetic interference that effected the functionality of the electrical components worn by miners by the 3M Versaflo TR-800 PAPR at the mines listed.

The investigator first performed baseline functionality tests for all electrical equipment including the PAPR by operating them individually away from one another. Testing was then conducted by positioning the running PAPR in various orientations and distances ranging from 12 inches to zero inches from miner-worn or carried battery powered electrical equipment.

| Equipment Type | Equipment Model | Mine ID used | Interference |

|---|---|---|---|

| Matrix Proximity |

|

All 4 mines | None |

| Industrial Scientific | Altair 4x | All 4 mines | None |

| CSE Methane Detector | 102LD | All 4 mines | None |

| Tracking and Communication |

Matrix METS-T1000 Leaky Feeder- Kenwood Hand Held Two-Way Radio TK-290VHF |

46-09319, 46-09217 | None |

| Tracking and Comm. |

IWT Wireless Mesh System |

46-09563 | None |

| Tracking and Communication |

Strata Wireless Mesh 23-A100008-0 Tracking Tag and Texting device |

46-09514 | None |

| Methane Monitor | CSE 140B-LD | All 4 mines | None |

| Remote Control |

Joy TX 3 Joy XR2 Battery Pack |

All 4 mines | None |

| Koehler Permissible Cap Lamps | 08209 | All 4 mines | None |

The Versaflo TR-800 features a helmet with a visor that flips up, connected by a hose to the fan motor/ battery pack which mounts on a belt.

The petitioner alleges that the alternative method proposed in the submitted petition will, at all times, guarantee no less than the same measure of protection afforded by the standard.

Intrinsic Safety Description

Information regarding the UL listing for the Versaflo TR-800 and the CleanSpace EX PAPRs was previously submitted to the MSHA Approval and Certification Center (A&CC). A review was requested for the use of these unapproved PAPRs in areas of mines where permissibility is required. A&CC conducted the reviews and concluded that:

1. The Versaflo TR-800 PAPR is certified by UL according to the ANSI/UL 60079-11 standard. The UL certificate allows 3M to mark the device as “Ex ia I”, meaning that the unit is certified to be used in hazardous locations (“Ex”), has met the most onerous level of intrinsic safety protection (“ia”), and the Equipment Protection Level (“very high”) is acceptable for use in mines susceptible to firedamp (“I”). Due to legal and regulatory constraints, the UL certificate alone is not sufficient approval.

2. The CleanSpace EX is certified by TestSafe Australia (TSA) according to the International Electrotechnical Commission (IEC) 60079-0:2011 (General Requirements) and IEC 60079-11:2011 (Intrinsic Safety) standards. The certificate allows PAFtec to mark the device as "Ex ib IIB T4 Gb" and "Ex ia I Ma." Due to legal and regulatory constraints, the TSA certificate is not accepted by MSHA as evidence that the PAPR is approved for use in U.S. mines.

Like the Versaflo TR-800, the CleanSpace EX is certified to be used in hazardous locations, meets the most onerous level of intrinsic safety protection, is acceptable for use in mining locations, the Equipment Protection Level is "very high", appropriate for use in mines susceptible to firedamp. In addition, its security is sufficient that it is unlikely to become an ignition source in normal operation, during expected malfunctions, or during rare malfunctions, even when left energized in the presence of an outbreak of gas (“Ma”).

NIOSH researchers, in a paper titled “An Evaluation of the Relative Safety of U.S. Mining Explosion-Protected Equipment Approval Requirements versus those of International Standards”, have determined that equipment which meets two-fault intrinsic safety as defined in the ANSI/UL 60079 standard would provide at least an equivalent level of safety as that provided by equipment approved to MSHA criteria.

The UL certifications, TSA certifications, and 3M and PAFtec listing materials (drawings, certificate and text report) were found to support the conclusion that both the Versaflo TR-800 and the CleanSpace EX meet the ANSI/UL standard’s “two fault” intrinsic safety requirements for mining equipment.

The Versaflo TR-800 carries an ingress protection rating of IP64. The CleanSpace EX carries an ingress protection rating of IP66. Both ratings exceed the minimum rating of IP54 required by the ANSI/UL and IEC standards for intrinsically safe mining equipment.

Electromagnetic Interference Investigation

Review of the submitted materials indicate that both units, as unintentional radiators, have been tested and found to meet Federal Communications Commission (FCC) Title 47, Code of Federal Regulations, Part 15 requirements for digital devices for use in typical industrial environments. This means that, under the test conditions and in industrial environments, they were found to not cause harmful interference.

Nevertheless, MSHA investigators tested the equipment in the mines to determine if PAPR electrical components such as the pump motor or battery create interference when used in close proximity to other electrical equipment.

Conclusion

When operating or working near continuous mining machines equipped with PDS, the manufacturer recommends a minimum separation distance of six inches between PDS MWCs and other electronic equipment to sufficiently reduce or eliminate interference. (See Appendix 1 for example diagrams of proper PAPR and PDS positioning on the body.)

When the PDS manufacturer’s recommendations requiring a six-inch separation between the PDS MWCs and the PAPRs’ battery pack or motor/blower were followed, MSHA testing showed no apparent interference or performance issues between the PAPRs and the electrical equipment tested typically worn, carried, or used on the CMM Sections (as detailed in Table 1 above).

Miner training should incorporate the importance of adhering to the PDS manufacturer’s recommendations so there is no interference between the PDS and PAPRs.

Based on the investigation discussed above, MSHA determined that the Versaflo TR-800 can be safely used where permissible equipment is required inby the last open crosscut, if the operator follows all the manufacturer’s recommendations and adheres to the Terms and Conditions of the Proposed Decision and Order.

On the basis of the petition and MSHA’s investigation findings, and the foregoing reasons, Greenbrier Minerals, LLC is granted a modification of the application of 30C.F.R. § 75.507-1(a) at its Eagle No. 1 Mine, Lower War Eagle, Muddy Bridge, and Powellton #1 Mine.

ORDER

Wherefore, pursuant to the authority delegated by the Secretary of Labor to the Administrator for Mine Safety and Health Enforcement and pursuant to Section 101(c) of the Federal Mine Safety and Health Act of 1977, 30 U.S.C. § 811(c), it is ordered that Greenbrier Minerals, LLC’s Petition for Modification of the application of 30 C.F.R. § 75.507-1(a) in the Eagle No. 1 Mine, Lower War Eagle, Muddy Bridge, and Powellton #1 Mine is hereby:

GRANTED, for the operator, who may use the non-permissible Versaflo TR-800 Powered Air Purifying Respirator (PAPR) inby the last open crosscut until such time that MSHA-approved permissible PAPR devices are available, subject to the conditions of this Order:

Terms and Conditions

1. Affected mine employees must be trained in the proper use and maintenance of the PAPR(s) to be used at the mine, the Versaflo TR-800 and/or the CleanSpace EX, in accordance with established manufacturer guidelines. This training shall alert the affected employees that neither the Versaflo TR-800 nor the CleanSpace EX PAPR is approved under 30 C.F.R. Part 18 and therefore must be de-energized when 1.0 or more percent methane is detected. The training shall also include the proper method to de-energize these PAPRs. In addition to the manufacturer’s guidelines, MSHA requires that mine employees be trained to examine the units before use to determine if any damage to the units exists that would negatively impact intrinsic safety, or any of the stipulations in this petition

2. The PAPRs, battery packs, all associated wiring and connections must be examined by a qualified person before use to determine if there are any observable defects or damage to the units that would negatively impact intrinsic safety. If any defect or damage is found, the PAPR must be removed from service.

3. Each PAPR shall be assigned a unique identification number. The operator shall maintain a separate logbook for the Versaflo TR-800 and CleanSpace EX PAPRs.

The logbooks shall be kept with the equipment or in a location with other mine record books and be made available to MSHA upon request. The equipment shall be examined at least weekly by a qualified person as defined in 30 C.F.R. § 75.512-1 and the examination results recorded in the logbook. Since float coal dust is removed by the air filter prior to reaching the motor, the PAPR user shall conduct regular examinations of the filter and perform periodic testing for proper operation of the “high filter load alarm” on the Versaflo TR-800 PAPR, and the “blocked filter” alarm on the CleanSpace EX PAPR. PAPR examination entries may be expunged after one year.

4. In addition to the “blocked filter” alarm on the CleanSpace EX PAPR, these units have a visual green/red filter indicator that turns red when the filter needs to be replaced. The mine shall stock an adequate supply of new CleanSpace EX filters and pre-filters.

5. All Versaflo TR-800 and CleanSpace EX PAPRs to be used inby the last open crosscut shall be physically examined by a qualified person as defined in 30 C.F.R.§ 75.151 prior to initial use. Each unit shall be examined by the person to operate the equipment prior to taking the equipment underground to ensure the equipment is used according to the original equipment manufacturer’s recommendations and maintained in a safe operating condition.

The examinations for the Versaflo TR-800 PAPRs shall include:

a. Check the equipment for any physical damage and the integrity of the case;

b. Remove the battery and examine for corrosion;

c. Inspect the contact points to ensure a secure connection to the battery;

d. Reinsert the battery and power up and shut down to ensure proper connections;

e. Check the battery compartment cover or battery attachment to ensure that it is securely fastened; and

f. For equipment utilizing lithium type cells, ensure that lithium cells and/or packs are not damaged or swollen.

The CleanSpace EX PAPR does not have an accessible/removable battery. The internal battery and motor/blower assembly are both contained within the sealed “power unit” assembly and the battery cannot be removed, reinserted, or fastened. Therefore, examination of the CleanSpace EX PAPR should include any indications of physical damage.

The operator is to ensure that all Versaflo TR-800 and CleanSpace EX PAPR units are serviced according to the manufacturer's recommendations. Dates of service shall be recorded in the equipment's logbook and shall include a description of the work performed.

6. The Versaflo TR-800 and CleanSpace EX PAPR units that will be used inby the last open crosscut shall not be put into service until MSHA has initially inspected the equipment and determined that it is compliant with all the terms and conditions of this Order.

7. Prior to energizing the Versaflo TR-800 or the CleanSpace EX PAPR inby the last open crosscut, methane tests must be made in accordance with 30 C.F.R. § 75.323(a).

8. All hand-held methane detectors shall be MSHA-approved and maintained in permissible and proper operating condition. All methane detectors must provide visual and audible warnings when methane is detected in concentrations at or above1.0 percent.

9. A qualified person shall continuously monitor for methane immediately before and during the use of the Versaflo TR-800 or CleanSpace EX PAPR inby the last open crosscut.

10. Neither the Versaflo TR-800 nor the CleanSpace EX PAPR shall be used if methane is detected in concentrations at or above 1.0 percent. When 1.0 percent or more methane is detected while the Versaflo TR-800 or CleanSpace EX PAPR is being used inby the last open crosscut, the equipment shall be de-energized immediately and the equipment withdrawn from the area.

11. In the Versaflo TR-800, use only 3M TR-830 Battery Pack (TR-800 Battery Pack), which meets lithium battery safety standard UL 1642 or IEC 62133. In the CleanSpace EX, use only the CleanSpace EX Power Unit, which meets the same UL or IEC lithium battery safety standards.

12. Before each shift when the Versaflo TR-800 or CleanSpace EX PAPR is to be used, all batteries and power units for the equipment must be charged sufficiently for the expected usage on that shift. If spare battery packs for the Versaflo TR-800 PAPR are provided, all battery “change outs” must occur in intake air outby the last open crosscut.

13. The following maintenance and use conditions shall apply to equipment containing lithium-type batteries:

a. Neither the TR-830 Battery Pack nor the CleanSpace EX Power Unit may be disassembled nor modified by anyone other than permitted by the manufacturer of the equipment.

b. The TR-830 Battery Pack shall be charged only on the surface of the mine, and only using a manufacturer’s recommended battery charger, such as:

i. 3M Battery Charger Kit TR-641N, which includes one 3M Charger Cradle TR-640 and one 3M Power Supply TR-941N, or,

ii. 3M 4-Station Battery Charger Kit TR-644N, which includes four 3M Charger Cradles TR-640 and one 3M, 4-Station Battery Charger Base/Power Supply TR-944N.

c. The CleanSpace EX internal battery, which is contained within the power unit assembly, shall be charged only on the surface of the mine, and only using the manufacturer’s recommended battery charger, such as the CleanSpace EX Battery Charger, Product Code PAF-0066.

d. Neither the TR-830 Battery Pack nor the CleanSpace EX power unit, which contains the internal battery, shall be exposed to water, allowed to get wet, or immersed in liquid. This does not preclude incidental exposure of the TR-830battery pack or the CleanSpace EX power unit assembly.

e. Neither the Versaflo TR-800 PAPR nor the CleanSpace EX PAPR, including the internal battery, shall be used, charged, or stored in locations where the manufacturer’s recommended temperature limits are exceeded. Neither the Versaflo TR-800 PAPR nor the CleanSpace EX PAPR shall be placed in direct sunlight nor stored near a source of heat.

f. Neither the TR-830 battery pack nor the CleanSpace EX PAPR’s internal battery shall be used at the end of its life cycle (i.e., when there is a performance decrease of greater than 20% in battery-operated equipment). The TR-830 battery pack and the CleanSpace EX power unit containing the internal battery must be disposed of properly.

i. Follow the manufacturer’s recommendations and instructions. Check and monitor each unit’s run time. Observe and notate the initial run time that a new fully charged battery provides for powering the unit. A record of the initial run time and the date shall be made by a trained and competent person. This record shall not be expunged on an annual basis but must be retained until the PAPR and/or the battery is retired from service.

ii. Routinely check the battery’s charge status.

iii. Routinely monitor batteries that are approaching the end of their estimated service life.

iv. Remove the battery from service when the following conditions are met:

a. The battery run time drops below 80% of the new battery run time, or;

b. The battery charge time increases significantly.

v. Follow the storage instructions as recommended by the manufacturer. If the instructions were not followed for a battery stored or otherwise unused for an extended period or the battery has no charge remaining, consider it to be damaged. Do not attempt to recharge it or to use it. Remove it from service and replace it with a new battery.

14. Personnel engaged in the use of the Versaflo TR-800 and CleanSpace EX PAPRs shall be properly trained to recognize the hazards and limitations associated with the use of the equipment in areas where methane could be present. Affected mine employees shall also be trained to properly position their PDS MWC at least six inches from their PAPR’s battery/motor blower or battery/power unit to prevent interference. (See Appendix 1 for example diagrams of proper PAPR and PDS positioning on the body.) Also, personnel shall be trained regarding proper procedures for donning Self-Contained Self Rescuers (SCSRs) during a mine emergency while wearing the Versaflo TR-800 or CleanSpace EX PAPR. The mine operator shall submit proposed revisions to update the Mine Emergency Evacuation and Firefighting Program of Instruction under 30 C.F.R. § 75.1502.

15. Within 60 days after this Order becomes final, the operator shall submit proposed revisions for its approved 30 C.F.R. Part 48 training plans to the Mine Safety and Health Enforcement District Manager. These proposed revisions shall specify initial and refresher training regarding the terms and conditions stated in this Decision and Order. When training is conducted on the terms and conditions in this Order, an MSHA Certificate of Training (Form 5000-23) shall be completed. Comments shall be included on the Certificate of Training indicating that the training received was for use of the Versaflo TR-800 or CleanSpace EX PAPR.

16. All personnel who will be involved with or affected by the use of the Versaflo TR-800 or CleanSpace EX PAPRs shall receive training in accordance with 30 C.F.R. § 48.7 on the requirements of this Order within 60 days of the date this Order becomes final. Such training must be completed before any Versaflo TR-800 or CleanSpace EX PAPR can be used inby the last open crosscut. The operator shall keep a record of such training and provide such record to MSHA upon request.

17. The operator shall provide annual retraining to all personnel who will be involved with or affected by the use of the Versaflo TR-800 or CleanSpace EX PAPRs in accordance with 30 C.F.R. § 48.8. The operator shall train new miners on the requirements of this Order in accordance with 30 C.F.R. § 48.5 and shall train experienced miners on the requirements of this Order in accordance with30 C.F.R. § 48.6. The operator shall keep a record of such training and provide such record to MSHA upon request.

18. The operator shall post this Order in unobstructed locations on the bulletin boards and/or in other conspicuous places where notices to miners are ordinarily posted, for a period of not less than 60 consecutive days.

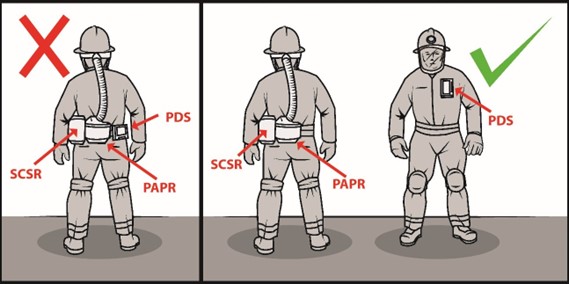

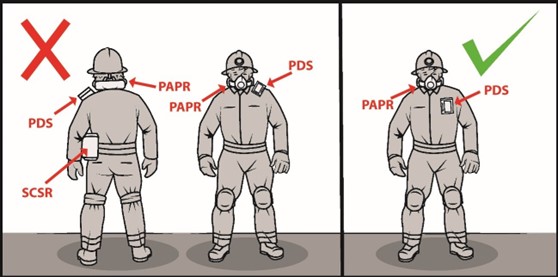

Appendix 1 – PAPR and PDS Positioning

When using a PAPR in conjunction with a Proximity Detection System (PDS), ensure that the manufacturers’ instructions are followed. To prevent interference, maintain at least six inches of separation between the PAPR and PDS’s miner wearable component (MWC). The figures below show how miners can wear these devices with belt-worn and neck-supported PAPRs, maintain the recommended separation distances between the PAPR’s battery/motor blower and the MWC, and prevent such interference.

Figure 4. Proper position of the PDS’s MWC when using a belt-worn PAPR.

Figure 5. Proper position of the PDS’s MWC when using a neck-supported PAPR.

Unless specifically mentioned herein, nothing in this Order changes or supersedes the requirements otherwise in1posed by the Mine Act, other mandatory standards or regulations, or approved plans.

The petitioner shall include the above terms and conditions in the initial and annual refresher training as required in its approved Part 48 training plans to ensure that miners are aware of the stipulations contained in this petition.

Any party to this action desiring a hearing on this matter must file in accordance with 30 C.F.R. § 44.14 within 30 days. The request for hearing must be filed with the Administrator for Mine Safety and Health Enforcement, 200 Constitution Ave. NW. Suite 3522 Washington, DC 20210.

Any hearing request must contain a concise st11nmary of position on the issues of fact or law to be raised by the party requesting the hearing, including specific objections to the proposed decision. A party other than the Petitioner who has requested a hearing may also comment on all issues of fact or law presented in the petition, and any party to this action requesting a hearing may indicate a desired hearing site.

If no request for a hearing is filed within 30 days after service of this Proposed Decision and Order, the Decision and Order will become final and must be posted by the operator on the bulletin board at the mine.

Brian Goepfert

Administrator for

Mine Safety and Health Enforcement

Certificate of Service

I hereby certify that a copy of this proposed decision was served personally or mailed, postage paid, or provided by other electronic means this 27th day of February, 2025, to:

Jamey New

Underground Mine Manager

Greenbrier Minerals, LLC

119 Rich Creek Road

Lyburn, WV 25632

jnew@coronadoglobal.com

Errol Scott Arnett

Safety and Health Specialist

cc: Frank Foster, Director

Office of Miners’ Health Safety and Training #7 Players Club Dr. Suite 2

Charleston, WV 25311 Frank.G.Foster@WV.gov

4. Proper position of the PDS’s MWC when using a belt-worn PAPR.

5. Proper position of the PDS’s MWC when using a neck-supported PAPR.