Accident Report: Fatality Reference

PDF Version

FAI-6412460-1

UNITED STATES

DEPARTMENT OF LABOR

MINE SAFETY AND HEALTH ADMINISTRATION

REPORT OF INVESTIGATION

Underground

(Lead-Zinc Ore)

Fatal Fall of Face, Rib, Side or Highwall Accident July 13, 2021

Immel Mine

Nyrstar Tennessee Mines, Strawberry Plains LLC Mascot, Knox County, Tennessee

ID No. 40-00170

Accident Investigators

Saul Akers

Mine Safety and Health Specialist

Scottie Sizemore

Mine Safety and Health Inspector

Originating Office

Mine Safety and Health Administration

Barbourville District

3837 S U.S. Hwy 25E

Barbourville, Kentucky 40906

Samuel R. Creasy, District Manager

OVERVIEW

On July 13, 2021 at 12:38 p.m., Gerald Turbyville, a 68 year-old high scaler with 10 years of mining experience, was fatally injured when a rock fell from the rib and struck him while he was performing scaling operations from the basket of a personnel lift.

The accident occurred because the mine operator did not: 1) promptly initiate appropriate action to correct hazardous conditions in high mine back (roof) and rib areas and maintain ground support where hazardous conditions existed, and in places where miners work or travel, and 2) take down or support the area before permitting scaling in the affected area.

GENERAL INFORMATION

Nyrstar Tennessee Mines, Strawberry Plains LLC, operates the Immel Mine, an underground lead-zinc mine in Mascot, Knox County, Tennessee. Immel Mine employs 114 miners and operates two 12-hour production shifts, seven days per week. The mine extracts lead-zinc ore by blasting. Miners use front end loaders to load the material into haul trucks and transport the ore to a hopper. The ore is fed from the hopper into a chute. Locomotives are used to move the train cars under the chute where ore is loaded and then transported to the underground dump. The ore is unloaded into a skip hoist that transports the ore to the surface.

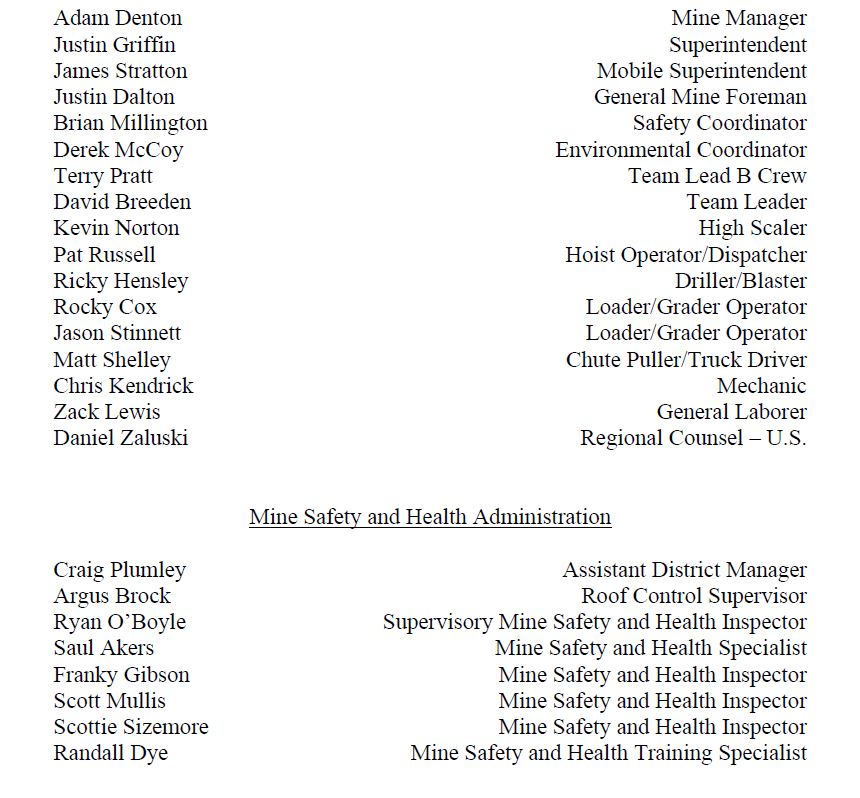

The principal management officials at the mine at the time of the accident were:

Adam Denton Mine Manager

Justin Griffin Superintendent

he Mine Safety and Health Administration (MSHA) completed the last regular safety and health inspection at this mine on June 17, 2021. At the time of the accident, MSHA had two inspectors at the mine conducting a regular safety and health inspection. The 2020 non-fatal days lost (NFDL) incident rate for the Immel Mine was zero, compared to the national average of 1.29 for mines of this type.

DESCRIPTION OF THE ACCIDENT

On July 13, 2021, Turbyville started his shift at 6:00 a.m. and attended a safety meeting on the surface with the utility crew. At approximately 6:30 a.m., Turbyville and Kevin Norton, High Scaler, traveled underground on the hoist to begin their duties. On the previous day, Justin Griffin, Superintendent, instructed Turbyville and Norton to scale in the 17W-3 area (see Appendix A).

Turbyville and Norton traveled by tractor and parked outside the 17W-3 area where a Genie S125 Telescopic Boom Lift (lift) was parked. Turbyville and Norton waited at the lift until Terry Pratt, Team Lead B Crew, moved a mechanical high scaler out of the 17W-3 entrance at approximately 9:30 a.m. This allowed Jason Stinnett, Loader/Grader Operator, to use a small loader to clear a berm barricading the entrance leading into the 17W-3 area. Afterward, Turbyville and Norton trammed and parked the lift near the 17W-3 area. Based on interviews, Turbyville, Norton, Stinnett, and Pratt accessed the 17W-3 area and concluded that the lift could not be trammed to a safe scaling position due to mud and rocks on the mine floor. The rocks were too large to be moved by the small loader.

Pratt directed Cox to bring a large loader to the 17W-3 area to move the large rocks. Rocky Cox, Loader/Grader Operator, trammed the large loader to the 17W-3 area and informed Pratt that rocks had fallen on the left side of the area where he worked the previous day. Cox further explained that he constructed a berm the previous day due to these conditions. Pratt told Cox not to move the large rocks with the loader because Pratt decided to break the rocks up by blasting them.

Pratt directed Turbyville and Norton to find something else to do the rest of the day while he worked to clear the large rocks to create a safe working place. Pratt traveled to the powder magazine to pick up explosives to blast the large rocks into smaller pieces. Pratt met Ricky Hensley, Driller/Blaster, at the powder magazine.

Before Pratt and Hensley returned, Griffin and Adam Denton, Mine Manager, arrived at the 17W-3 area at approximately 10:10 a.m. Based on interviews, Turbyville and Norton informed Griffin and Denton that they had some concerns regarding the assigned scaling operations.

Turbyville and Norton told Griffin and Denton that they could not properly set the lift under the brow (the low place in the roof) and scale the H-Pillar; they needed to scale the brow first. Griffin instructed Turbyville and Norton to position the lift between the H-Pillar and J-Pillar and scale the brow from there. After Turbyville and Norton scaled the brow, Griffin instructed Turbyville and Norton to reposition the lift to scale the H-Pillar ribs. Griffin and Denton left the area at approximately 10:30 a.m. Turbyville and Norton repositioned the lift and scaled another brow that was above the roadway leading to the 17W-3 area.

Pratt returned to the 17W-3 area with the blasting crew: Hensley, Matt Shelley, Chute Puller/Truck Driver, and Zack Lewis, General Laborer. Based on witness interviews, Pratt asked Turbyville and Norton what they were doing in the area. Norton informed Pratt that they scaled the brow as directed by Griffin and Denton. Pratt instructed Turbyville and Norton to move the lift out of 17W-3 so the large rocks could be blasted. After Turbyville and Norton moved the lift, Pratt, Hensley, Shelley, and Lewis loaded the explosives in the large rocks on the floor located on both sides of the H-Pillar. Pratt left the area to travel to another area of the mine. The blasting crew (Hensley, Shelley, and Lewis) informed Norton that the crew was ready to use the lift to assist in loading explosives into the rib crack on the left side of H-Pillar.

At 12:18 p.m., Turbyville trammed the lift to the inby edge of the brow. Hensley and Turbyville got into the lift basket, with Turbyville operating the controls. Hensley and Turbyville hand scaled a few small rocks from the face of the H-Pillar on the way up to the rib crack Hensley was preparing to load with explosives. Hensley loaded explosive material into the rib cracks, which extended approximately 10 feet to about 37 feet above the mine floor. Turbyville lowered the lift basket to get additional blasting supplies from Shelley, who was on the mine floor. Turbyville then raised the lift basket to allow Hensley to connect the shots with the detonator cord. At 12:38 p.m., as Turbyville raised the lift to approximately 11 feet off the mine floor, Hensley felt small rocks falling off the rib. Hensley laid down in the basket just as a large rock fell from the rib, striking Turbyville and the right side of the basket. Hensley was thrown out of the basket with his legs contacting the mine floor and his upper body hanging by the harness and lanyard, which were attached to the basket. Shelley was just a few steps away from the basket and ran from the falling rock. While running, Shelley fell and cut the left side of his forehead.

Norton and Lewis were behind the lift when the large rock fell, and Norton rushed to the accident scene to assess the conditions of the miners. Norton told Shelley to get help, then disconnected Hensley’s lanyard from the basket and lowered him to the mine floor. Norton was pulling Hensley to a safe location when Lewis came back. Norton and Lewis worked to get Hensley to the rear of the lift. Norton went back to the basket and checked Turbyville for a pulse, but did not detect one.

Justin Dalton, General Mine Foreman, was traveling out of the mine with Franky Gibson and Scott Mullis, MSHA Mine Safety and Health Inspectors, when he heard the call for help on his radio. Gibson and Mullis had been conducting regular inspection activities and were in the process of leaving the mine. Dalton contacted Pat Russell, Hoist Operator/Dispatcher, and told him to call 911.

Dalton, Gibson, and Mullis traveled to the accident scene. Dalton checked Turbyville for a pulse, but did not detect one. Chris Kendrick, Mechanic, traveled to the shop for first aid supplies and returned to the accident scene. Kendrick, Shelley, and Norton put a neck brace on Hensley, placed him on a backboard, and transported him to the surface. Kendrick, Shelley, Norton, and Hensley arrived on the surface at approximately 1:20 p.m. American Medical Responses, Inc. (AMR) took over medical treatment at that point. AMR transported Hensley and Shelley in the same ambulance to the University of Tennessee Medical Center.

Denton and Griffin arrived at the accident scene to help retrieve Turbyville. Denton directed Dalton and James Stratton, Mobile Superintendent, to go to the shop, get a loader, tow cable, and clevises to pull the lift back to a safe location. When Dalton and Stratton returned, Dalton and Griffin turned the wheel blocks around on the lift to release its brakes. The loader, operated by Dalton, was connected to the lift and Dalton pulled the lift back to a safe location to remove Turbyville from the basket. Denton, Griffin, Dalton, and Stratton retrieved Turbyville from the lift basket, and placed him on a stretcher to transport him out of the mine. They arrived on the surface at approximately 2:30 p.m. Dr. Travis Danielsen, Assistant Medical Examiner with the Knox County Regional Forensic Center, was on the surface of the mine and pronounced Turbyville dead at 2:33 p.m.

INVESTIGATION OF THE ACCIDENT

On July 13, 2021, at 1:19 p.m., Derek McCoy, Environmental Coordinator, contacted the Department of Labor National Contact Center (DOLNCC) to report an accident. At 1:40 p.m., the DOLNCC contacted Dennis Cotton, Assistant District Manager, who then contacted Argus Brock, Roof Control Supervisor, and Craig Plumley, Assistant District Manager. Brock sent Saul Akers, Mine Safety and Health Specialist, to the mine to serve as the lead accident investigator. At 2:29 p.m., McCoy contacted Plumley and said that there were two other victims involved in the accident and both were being taken to the University of Tennessee Medical Center.

Gibson and Mullis had finished inspection activities for the day and were traveling toward the main elevator to exit the mine with Dalton when the accident occurred. They were accompanied by Dalton when he heard the call for help on his radio. At 12:50 p.m., Gibson, Mullis, and Dalton arrived at the accident scene. Gibson issued an order under the provisions of Section 103(k) of the Mine Act to assure the safety of miners and preservation of evidence. At 4:30 p.m., Plumley and Brock arrived at the mine, followed shortly after by Akers. The investigators reviewed details of the accident and traveled underground to conduct the initial investigation of the accident scene. On July 14, 2021, Akers, Brock and Ryan O’Boyle, Supervisory Mine Safety and Health Inspector, traveled underground to continue the investigation at the accident scene. Scottie Sizemore, Mine Safety and Health Inspector, assisted as a roof control specialist.

Investigators conducted interviews with miners and mine management at Nyrstar’s Training Facility at the Young Mine complex on July 14 and July 26, 2021. On July 23, 2021, investigators interviewed Hensley at his residence. See Appendix B for a list of persons participating in the accident investigation.

DISCUSSION

Location of the Accident

This accident occurred in the 17W-3 area of the mine, near the J-Pillar and H-Pillar.

Accident Scene and Geologic Conditions

Mining heights vary throughout the mine with some reaching 150 feet from the mine floor. The 17W-3 area is a collapse breccia (rock consisting of angular fragments cemented together), mined within the Ordovician Mascot and Kingsport Formations. The formations are characterized by highly contorted bedding, drag folds, tension fractures, and vertical offsets along small, normal faults. Drilling logs indicate that mining began in the 17W-3 area on March 3, 1975, and occurred sporadically afterward. The area had been benched three times since the initial development in 1975. Over 45 years, the 17W-3 area had deteriorated due to age and excessive mining as evidenced by the weakening of multiple joints resulting in sloughing of the mine ribs and roof. During the previous five years, the 17W-3 area had not been mined, with the exception of exploration drilling. Mining resumed in June 2021.

Interviews revealed that on the day prior to the accident, several rocks had fallen while miners loaded material onto trucks. This required further clean up and barricading of the area. There were several loose rocks laying on the mine floor that had fallen from either the ribs or the roof the day before. The rocks were too large for the loaders to move and had to be blasted to reduce their size. The mining height was normally 25 to 30 feet, but at the accident scene was 108 feet. The rock that struck Turbyville fell from the rib of the J-Pillar, located on the right side of the lift. The rock was 79 feet above the mine floor, weighed 3.32 tons, and measured approximately seven feet long, five feet wide, and 19 inches thick (see Appendix C).

Ground Control

The Immel Mine underground development uses the conventional room and pillar extraction method that results in a system of underground pillars and openings. The typical ground support system hardware used in Immel Mine at the time of the accident included 7 foot long split set type friction rock bolts and steel wire mesh.

In the 17W-3 area, several of the seven foot friction (split set) galvanized roof bolts were pulled from the mine roof and were visible in the fallen material. When ground support is necessary, the mine operator designs, installs, and maintains the support to control the ground in places where persons work or travel while performing their assigned tasks.

The Ground Support Policy for the Immel Mine, dated November 26, 2019, addresses measures that should be taken in the event of ground support failure. The mine operator evaluates ground support performance through observation and daily reporting. If a ground reinforcement incident occurs, field information about such an event, including the rock type, bolt length, bolt type, (e.g., steel or galvanized) mine location, time of incident after rock bolt installation, and presence of water, provide important insight into rock bolt performance. The policy requires: 1) miners to report rock bolt failures to the supervisor before any remedial measures are taken, and 2) placement of barriers into the affected area to prevent unauthorized entry. Miners and supervisors must report events, which are judged significant to the mine’s Safety Department, who follow up with a site inspection. A written summary concerning the reason for the failure is required. If possible, pictures are taken to document the event.

The mine operator had a remotely operated mechanical scaler at the mine. However, the 30-foot maximum vertical reach of the mechanical scaler was insufficient for the 108-foot-high area.

Equipment Involved

The miners involved in the accident were working in the basket of a Genie S125 Telescopic Boom Lift (lift). The lift has a maximum reach of 80 feet horizontally and 125 feet vertically. The gross vehicle weight and rated load was 45,100 pounds. Investigators inspected the lift and found no deficiencies.

Examinations

The investigators reviewed ground conditions in the area of the accident. The review found the mine operator did not correct or support hazardous ground conditions before allowing miners to work or travel in the area of the accident.

The broken, loose, and hanging rock and multiple joints were visible from the mine floor. The extent of these hazardous conditions were made clearer to the investigators when they viewed the area from an elevated idle working place. The joints were clearly visible and displayed signs of separation near the edge of the H-Pillar.

The accident investigation team examined the 17W-3 area and observed several large rocks laying loose on the mine floor. Some rocks were pushed up to the left and right side of the H-Pillar, indicating that previous falls were cleaned up. There were also several rocks laying on the mine floor, which had bolts remaining in them, and had dislodged from the J-Pillar rib during the accident. Several rocks were loose and overhanging above the brow area and around the left and right ribs.

On the left side of the H-Pillar, a vertical crack extended from the bottom of the pillar to approximately 37 feet above the mine floor. Miners were in the process of using explosives to remove the vertical rib crack. When observed from the upper left side, the top of the H-Pillar showed serious deterioration and loose, unconsolidated, potentially hazardous material. The adjacent pillar (J-Pillar) had an overhanging rock near the top of the rib, and it was clear to investigators that some rock had broken loose and fallen, leaving additional loose rock hanging. Investigators determined that the lift being used to scale the area could not be placed in a safe location while scaling.

Prudent examinations of ground conditions include observations from multiple vantage points to assure hazardous conditions are identified and corrected before miners work or travel in the affected area. Investigators determined that an adequate examination would have recognized and corrected these safety hazards prior to allowing miners to enter and work in the affected area. Several mine supervisors were in the 17W-3 area and discussed the positioning of the lift in the unsafe area and could have corrected these safety hazards prior to allowing miners to enter and work in the affected area.

In addition, the mine operator’s Ground Support Policy, dated November 26, 2019, states that all miners are responsible for inspecting their workplace, as well as checking and reporting on ground conditions. If conditions in a working place or travelway are determined to be hazardous, access to the area shall be restricted to authorized personnel only while the hazard is corrected. A physical form, referred to as a Workplace Inspection Card, is carried and completed by each miner, according to a job task and/or working place, which assures an inspection of the work area has been completed. Investigators determined that the mine operator did not assure miners followed the established Ground Support Policy to correct ground hazardous conditions before permitting work or travel in the affected area.

Training and Experience

Turbyville had over 10 years of mining experience, all at the Immel Mine. He worked as ground support/high scaler for over 6 years. Randall Dye, Mine Safety and Health Training Specialist, reviewed training records for Turbyville, Hensley, and Shelley. Turbyville received the annual refresher training on July 7, 2021, and task training on the lift on June 8, 2015. A review of the mine operator’s training records found the mine operator conducted all training in accordance with MSHA Part 48 training regulations.

Dye found that Hensley and Shelley also received all training in accordance with MSHA Part 48 training regulations.

ROOT CAUSE ANALYSIS

The accident investigation team conducted an analysis to identify the underlying causes of the accident. The team identified the following root causes, and the mine operator implemented the corresponding corrective actions to prevent a recurrence.

1. Root Cause: The mine operator did not promptly initiate appropriate action to correct hazardous ground conditions in high mine roof and rib areas, before permitting work or travel in the affected area.

Corrective Action: The mine operator identified and examined all high mine roof and rib areas with the expertise of geologists, engineers, and mine management. The mine operator implemented written procedures that address scaling, meshing, and additional support to correct hazardous conditions when encountered. The mine operator trained miners on the new written procedures.

2. Root Cause: The mine operator did not take down or support hazardous roof and ribs before permitting scalers to scale below the hazardous roof and ribs.

Corrective Action: The mine operator implemented written procedures for the development of future high roof areas, which includes eliminating any areas that cannot be mechanically scaled. All miners have been trained on the procedures.

3. Root Cause: The mine operator did not maintain ground support where hazardous conditions existed and in places where miners work or travel.

Corrective Action: The mine operator implemented a written procedure for any area that has the potential to become a high roof area, defined as areas having roof heights over 35 feet high. These areas will be pattern-bolted with screen which extends a minimum of 3 feet down the rib. The screen must extend down the ribs/pillars/brows/overhangs to a level where proper ground control support activities can be undertaken by the equipment. All miners have been trained in the new procedure.

CONCLUSION

On July 13, 2021 at 12:38 p.m., Gerald Turbyville, a 68 year-old high scaler with 10 years of mining experience, was fatally injured when a rock fell from the rib and struck him while he was performing scaling operations from the basket of a personnel lift.

The accident occurred because the mine operator did not: 1) promptly initiate appropriate action to correct hazardous conditions in high mine back (roof) and rib areas and maintain ground support where hazardous conditions existed, and in places where miners work or travel, and 2) take down or support the area before permitting scaling in the affected area.

Approved by:

Samuel R. Creasy Date

District Manager

ENFORCEMENT ACTIONS

1. A 103(k) order was issued to Nyrstar Tennessee Mines, Strawberry Plains LLC:

A fatal accident occurred on July 13, 2021 at approximately 12:38pm. This order is being issued under the authority of the Federal Mine Safety and Health Act of 1977, under Section 103(k) to insure the safety of all persons at the mine, and requires the operator to obtain the approval of an authorized representative of MSHA of any plan to recover any person in the mine or to recover the mine or affected area. This order prohibits any activity in the affected area. The operator is reminded of the obligation to preserve all evidence that would aid in investigating the cause or causes of the accident in accordance with 30 CFR 50.12.

2. A 104(d)(1) citation was issued to Nyrstar Tennessee Mines, Strawberry Plains LLC for violation of 30 CFR § 57.3200.

A fatal accident occurred at this mine in the 17W-3 area because hazardous, loose ground conditions that created hazards to persons were not taken down or supported before other work was permitted in the area. Drilling logs indicate that mining began in the 17W-3 area on March 3, 1975. Development of this area involved periodic mine floor benching on three occasions to a depth of about 30 feet each cycle, resulting in the 108-foot room height at the time of the accident. The 17W-3 area had been idle for the past five years, with the exception of exploration drilling, until June 2021, when the mine operator attempted to resume production in the 17W-3 area by performing additional benching. Over 45 years, the 17W-3 area had deteriorated due to age, weathering, and excessive mining without the mine operator adequately addressing the declining conditions as evidenced by the following hazardous conditions:

1. The upper left side near the top of H-Pillar showed serious deterioration and loose unconsolidated material. On the lower left side of the H-Pillar, a vertical crack extended from the bottom of the pillar to approximately 37 feet above the mine floor. Miners were in the process of using explosives to remove the vertical rib crack, as hand scaling had been unsuccessful, prior to the accident.

2. The adjacent J-Pillar had separated, overhanging rock near the top of the rib pillar. It was obvious from the clean rock face that rock had recently broken loose and fallen, leaving additional loose rock and dislodged rib bolts hanging from near the top of J-Pillar.

3. Large loose rock was observed on the mine floor of the 17W-3 area from previous rib falls that dislodged several seven-foot friction (split set) galvanized rib bolts. This rubble material with failed rib bolts exposed had been pushed up to the left and right side of the H-Pillar in the days prior to the accident, with no attempt by the mine operator to re-support the areas where rib bolts were dislodged.

4. On the day before the accident, a front-end loader operator was loading trucks in the 17W-3 area when rocks fell onto the front-end loader. This prompted the front-end loader operator to barricade the 17W-3 area from entry.

5. These growing hazards culminated on the day of the accident when a rock fell from the rib of J-Pillar, 79 feet above the mine floor. The rock weighed 3.32 tons and fatally injured one miner and severely injured a second miner. Several of the seven-foot friction (split set) galvanized roof bolts were pulled from the mine rib and were visible in the fallen material.

The mine operator allowed these hazardous conditions to persist while directing miners to work and travel in the 17W-3 area. Conditions were too severe to be addressed by the means available to the miners and did not afford safe locations from which the miners could work to correct the conditions. The experienced scaling crew had declined to enter the 17W-3 area due to the hazardous conditions. However, mine management personnel, upon examining the site, instructed the miners to enter the 17W-3 area for scaling. The mine operator engaged in aggravated conduct constituting more than ordinary negligence by not correcting hazardous ground conditions and for permitting work in the unsafe area. This violation is an unwarrantable failure to comply with a mandatory standard.

3. A 104(d)(1) order was issued to Nyrstar Tennessee Mines, Strawberry Plains LLC for violation of 30 CFR § 57.3201.

A fatal accident occurred at this mine when the mine operator did not protect two miners who were scaling ribs from the basket of a Genie S125 Telescopic Boom Lift in the 17W-3 area. This method of scaling exposed the miners to injury because of the following obvious and extensive hazardous ground conditions in this area, with no other protection provided for these miners:

1. The upper left side near the top of H-Pillar showed serious deterioration and loose unconsolidated material. On the lower left side of the H-Pillar, a vertical crack extended from the bottom of the pillar to approximately 37 feet above the mine floor. Miners were in the process of using explosives to remove the vertical rib crack, as hand scaling had been attempted and unsuccessful, prior to the accident.

2. The adjacent J-Pillar had separated, overhanging rock near the top of the rib pillar. It was obvious from the clean rock face that rock had recently broken loose and fallen, leaving additional loose rock and dislodged rib bolts hanging from near the top of J Pillar. The damaged rib support was not repaired nor replaced. Loose, separated rock on J-Pillar was attempted to be hand-scaled by miners, prior to the accident.

3. These growing hazards culminated on the day of the accident when a rock fell from the rib of J-Pillar, 79 feet above the mine floor. The rock weighed 3.32 tons and fatally injured one miner and severely injured a second miner. Several of the seven-foot friction (split set) galvanized roof bolts were pulled from the mine rib and were visible in the fallen material.

The mine operator allowed these hazardous conditions to persist while directing miners to work and travel in the 17W-3 area. Conditions were too severe to be addressed by hand scaling and did not afford safe locations from which the miners could work to correct the conditions. The experienced scaling crew had declined to enter the 17W-3 area, due to the hazardous conditions. However, mine management personnel, upon examining the site, instructed the miners to enter the 17W-3 area for scaling. The mine operator engaged in aggravated conduct constituting more than ordinary negligence by not correcting hazardous ground conditions and permitting work in the unsafe area. This violation is an unwarrantable failure to comply with a mandatory standard.

APPENDIX B - Persons Participating in the Investigation

Nyrstar Tennessee Mines, Strawberry Plains LLC