Safety Alert

Tension Bolt Failure

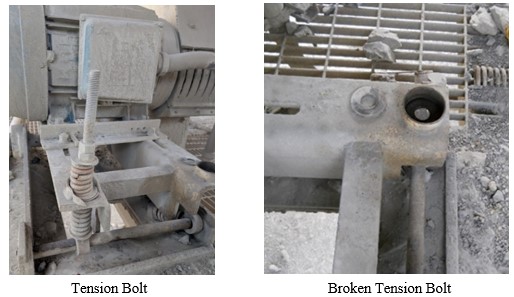

On July 17, 2025, a miner at a surface limestone operation sustained serious injuries while performing repairs on a belt drive motor. During the repair process, the motor’s tensioning system was being adjusted when a ¾-inch diameter all-thread tensioner bolt failed, causing the bolt to break loose and strike the miner in the face. Spring-integrated designs with constant pressure and continuous vibrations pose potential safety concerns.

Best Practices

- Ensure all miners receive thorough training to identify workplace hazards and perform tasks safely.

- Maintain all equipment and safety devices in proper working condition to ensure safe operation by reviewing manufacturer manuals prior to service; replace worn or damaged components; and use tightening sequences and tighten as recommended.

- Check component quality by examining bolts, washers, springs, and nuts for visible defects like rust, cracks, corrosion, thread damage or deformation.

- Conduct a risk assessment before starting work to identify and control all forms of stored energy, including mechanical, electrical, hydraulic, gravitational hazards, and unintended motion of equipment.

- Alignment matters: Ensure all components are properly aligned before bolt installation. Misalignment can lead to uneven stress distribution within the system, possibly leading to their premature failure.